Technologies

The Importance of TIM Analysis

Through standards and analytical instruments, comprehensive understanding of TIM's physical and thermal properties can be achieved, thereby optimizing their applications in electronic devices. This not only helps improve product reliability, but also reduces power consumption and extends device lifespan. When selecting appropriate analytical methods, factors such as sample morphology, pressure conditions, and temperature control requirements must be considered based on actual needs to obtain the most representative data.

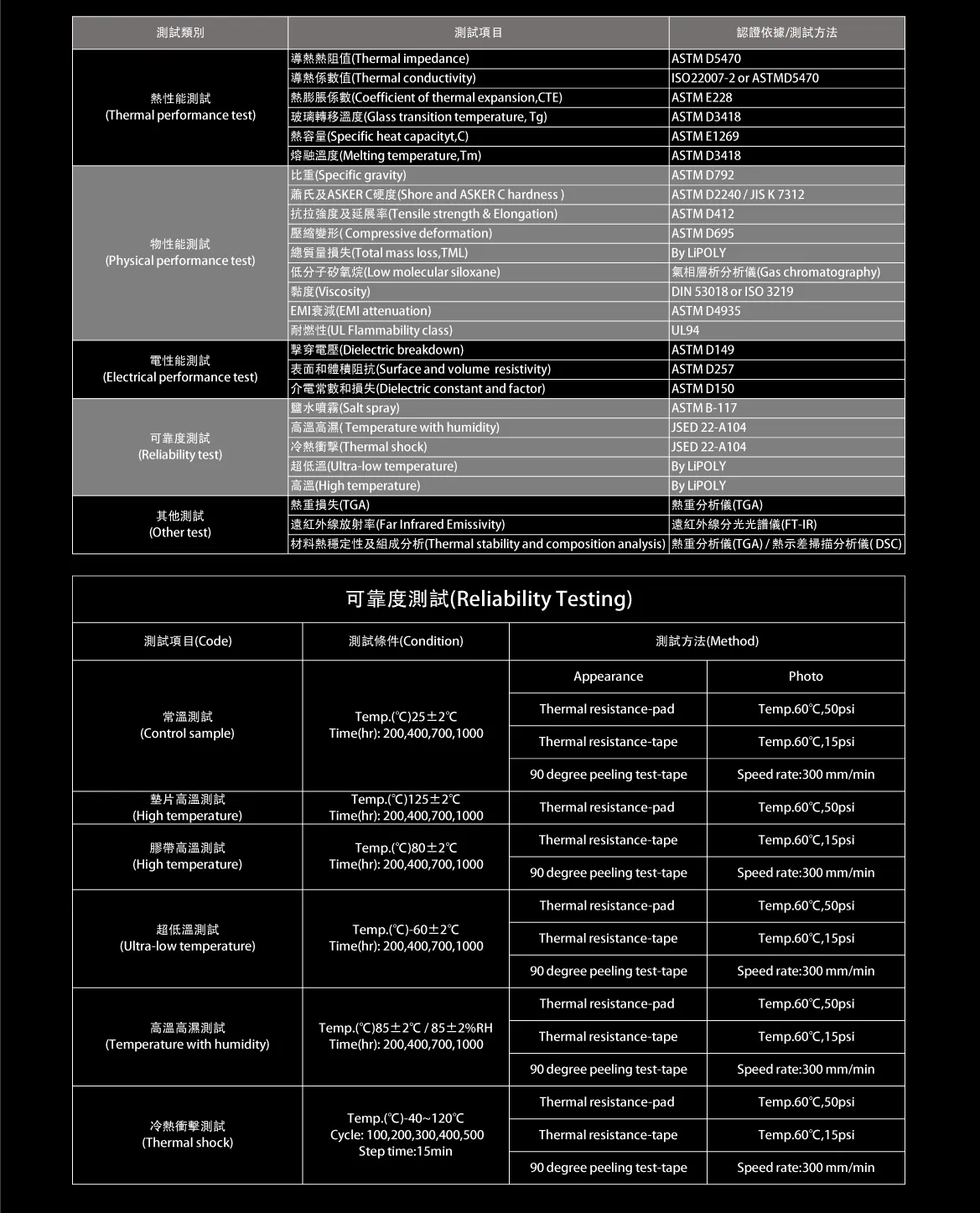

Testing Standards and Applications

ASTM D5470: Thermal Conductivity & Resistance Testing

ASTM D5470 is a standard method for evaluating the thermal conductivity and thermal resistance of TIM materials. During testing, the material is placed between two temperature-controlled metal blocks, and the thermal conductivity and interfacial thermal resistance of the material are calculated by measuring the temperature difference through steady-state heat flow. This method is suitable for paste, sheet, and other forms of TIM materials.

- Application Instruments:TIM testers (such as Analysis Tech TIM Tester) can rapidly measure the thermal conductivity and interfacial impedance of materials, and provide pressure and thickness variation data.

- Advantages:Precise evaluation of material performance under different pressure conditions, suitable for high thermal conductivity materials.

ASTM D374:Thickness Measurement

ASTM D374 is used for measuring the thickness of film or sheet materials, suitable for basic physical property testing of TIM. For example, in phase change materials, thickness variations affect their thermal conductivity performance, making accurate measurement crucial.

- Application Instruments:Electronic thickness gauges or contact-type thickness testing equipment.

- Application Scenarios:Verification of the impact of material thickness changes after phase change on thermal conductivity.

ASTM D792: Density Testing

ASTM D792 is a standard method for measuring material density through liquid displacement method, used to determine the specific gravity of TIM. This property has important implications for material filling efficiency and thermal performance.

- Application Instruments:Density meter or liquid displacement apparatus.

- Application Scenarios:Comparing the impact of different filler contents on TIM performance.

ASTM D2240: Hardness Testing

ASTM D2240 uses a Shore durometer to evaluate the hardness of TIM. Higher hardness typically indicates that the material is less prone to deformation, but may affect interfacial contact effectiveness.

- Application Instruments:Shore durometer.

- Application Scenarios:Selecting TIM suitable for use under specific pressure conditions.

ASTM D149: Insulation Testing

ASTM D149 is a standard test method for solid electrical insulating materials, primarily used to determine the dielectric breakdown voltage and dielectric strength of materials at commercial power frequencies.

- Application Instruments:Hipot tester (Dielectric strength tester).

- Application Scenarios:Analyzing TIM performance in high voltage environments and detecting characteristic changes due to processing, aging, or environmental factors.

| TEST METHOD | PROPERTY | Instrument Types | Application Ranges |

|---|---|---|---|

| ASTM D5470 | Thermal Conductivity/Resistance | TIM Tester | High Thermal Conductivity TIM Materials |

| ASTM D374 | Thickness | Electronic Thickness Gauge | Thickness Changes After Phase Transition |

| ASTM D792 | Density | Density Meter | Impact of Filler Content on Performance |

| ASTM D2240 | Hardness | Shore Hardness Tester | Pressure-Based Material Selection |

| ASTM D149 | Dielectric Breakdown | Hipot Tester | High Voltage Performance Analysis |