Liquid

Solid

Absorber

Tape

Light

Insulator

Graphite

Break

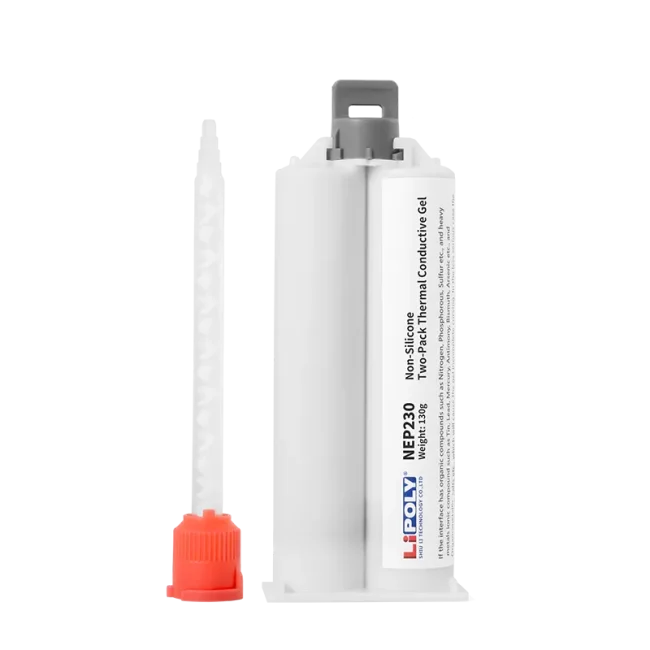

NEP230

3.0 W/m·K

Low outgassing

Adhesive

NEP230 is a non-silicone thermal gap filling adhesive that combines both thermal conductivity and bonding functions. It can cure at room temperature or elevated temperatures to provide strong fixation. Compared to thermal pads, thermal adhesives not only apply lower stress to components but also maintain insulation properties. With zero low-molecular-weight siloxane volatility, it does not cause electrical contact failure, making it suitable for use in optical products or sensitive electronic components.

FEATURES

/ Thermal conductivity: 3.0 W/m·K

/ Suitable for automatic dispensing machine

/ Room Temperature curing or heating curing

/ Low compression stress during assembly

/ Excellent adhesion to metal & PCB

CONFIGURATIONS

/ Cartridges: 50ml, 400ml

/ Other special and custom sizes are available upon request

TYPICAL APPLICATION

/ Electronic components: IC、CPU MOS、Mother Board、Wireless Hub Telecom Device 、Automotive electronics、Computer 、 Peripherals and High frequency magnetic inductor

/ Between any heat-generating component and a heat sink

/ 5G base station & infrastructure

/ EV electric vehicle

TYPICAL PROPERTIES

| PROPERTY | NEP230 | UNIT | TEST METHOD |

|---|---|---|---|

| Color | Gray-A Black-B | - | Visual |

| Resin Base | Epoxy | - | - |

| A:B | 100:100 | - | - |

| Viscosity A | 270 | Pa.s | ISO 3219 |

| Viscosity B | 240 | Pa.s | ISO 3219 |

| Hardness | 90 | Shore A | ASTM D2240 |

| Tensile strength | 60 | N/cm² | ISO527 |

| ROHS & REACH | Compliant | - | - |

| THERMAL | |||

| Thermal conductivity | 3.0 | W/m·K | ISO 22007-2 |

| Dielectric breakdown | 14 | KV/mm | ASTM D149 |

| Volume resistivity | >10¹¹ | Ohm-m | ASTM D257 |

Related Products

Contact

Thermal Solutions Expert

LiPOLY® Advance TIMs

Taoyuan City, Bade District, Yongfeng Road, No. 435

Contact