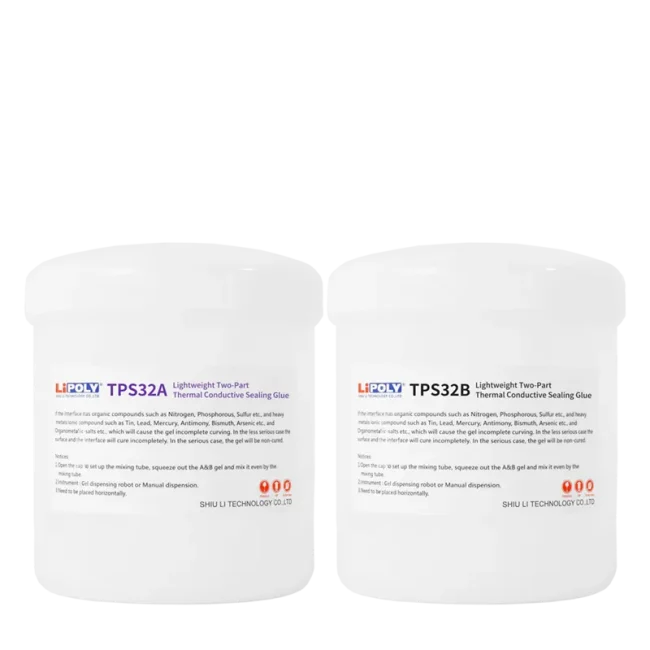

Encapsulants

Low-Density Electronic Potting Compound : TPS32 Potting Compound: TPS32 features excellent thermal conductivity with ultra-low density of 1.72 g/cm³.

This potting compoundmaterial reduces damage risks from external environment factors. It is suitable for drone power module encapsulation and enables thin-profile designs.

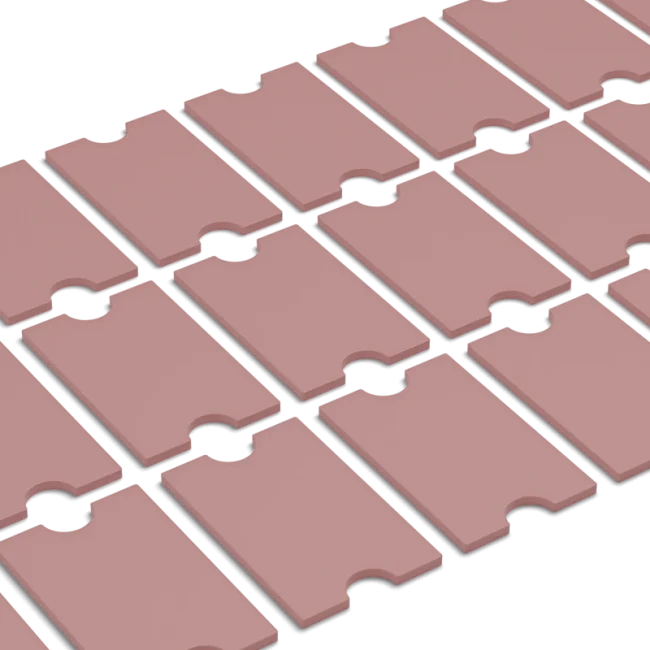

Thermal Putty

Low-Density Thermal Putty : DTT10-s provides 10.0 W/m·K thermal conductivity with a density of only 2.6 g/cm³.

It can be applied directly to electronic components, reducing stress on components while suitable for automated production.

Heat Dissipation Fins and Natural Convection Design

- Aluminum heat dissipation fins combined with vapor chamber design can effectively distribute heat generated by batteries and electronic components evenly and dissipate through natural convection. This design requires no additional power for fan operation, making it ideal for lightweight requirements.

Technological Innovation Applications

- Aerodynamic Heat Dissipation: Some drones utilize airflow generated by propeller movement for passive cooling. DJI Mavic Mini adopts a fanless design, improving heat dissipation efficiency through redesigned airflow channels.

- Artificial Intelligence Optimization: Using Physics-Informed Machine Learning (PIML) for fin design optimization can rapidly find optimal parameter configurations, improving heat dissipation efficiency and reducing development costs.

- Aerodynamic Heat Dissipation: Some drones utilize airflow generated by propeller movement for passive cooling. DJI Mavic Mini adopts a fanless design, improving heat dissipation efficiency through redesigned airflow channels.

Future Development Directions

As drone applications diversify, lightweight thermal materials will continue developing in these directions:

- Higher thermal conductivity and high-temperature resistance

- Combined lightweight and environmental characteristics, using renewable or biodegradable materials

- Automated production compatibility to reduce large-scale production costs