FEATURES

/ Thermal conductivity: 24.0 W/m·K

/ High compression rate

/ Extremely low thermal impedance

CONFIGURATIONS

/ Sheets form

/ Die-cuts parts

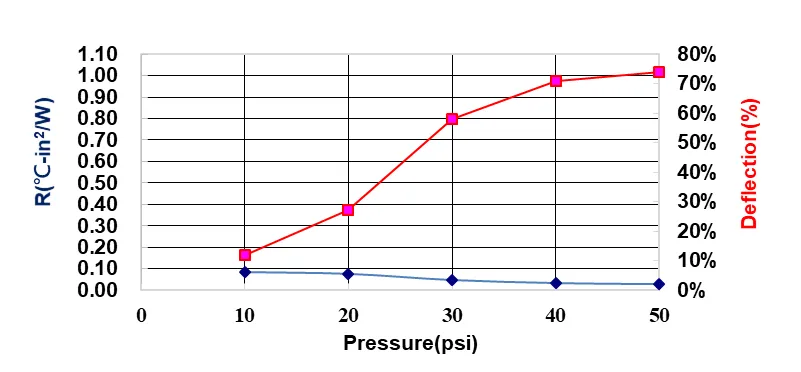

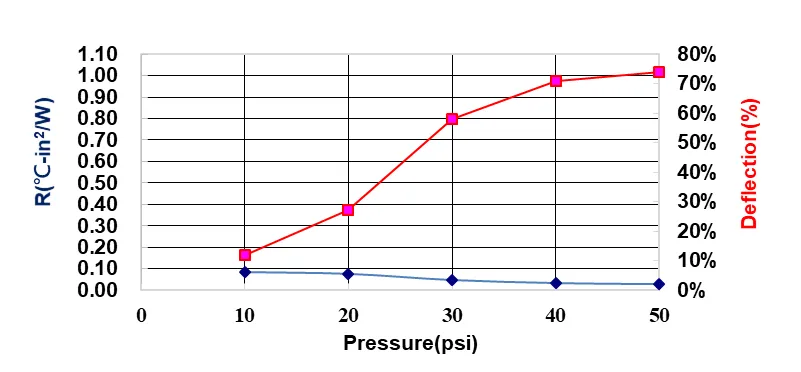

Thermal Resistance vs. Pressure vs. Deflection

NEW Product

/ Thermal conductivity: 24.0 W/m·K

/ High compression rate

/ Extremely low thermal impedance

/ Sheets form

/ Die-cuts parts

/ Between CPU and heat sink

/ Between a component and heat sink

/ Flat-panel displays

/ Power supplies

/ High speed mass storage drives

/ Telecommunication hardware

/ 5G base station & infrastructure

/ High-end Chip

| PROPERTY | Super Thermal Pad | UNIT | TEST METHOD |

|---|---|---|---|

| Color | Gray | - | Visual |

| Surface tack 2-side/1-side | 2 | - | - |

| Thickness | Customized | mm | ASTM D374 |

| Density | 3.3 | g/cm³ | ASTM D792 |

| Hardness | 70 | Shore OOO | ASTM D2240 |

| TML | <0.1 | % | By LiPOLY |

| Application temperature | -60~150 | °C | - |

| ROHS & REACH | Compliant | ||

| THERMAL | |||

| Thermal conductivity | 24.0 | W/m*K | ASTM D5470 |

| Thermal conductivity | 15.0 | W/m*K | ISO 22007-2 |

| Thermal impedance@10psi | 0.085 | ° C-in²/ W | ASTM D5470 |

Thermal Solutions Expert

LiPOLY® Advance TIMs

Taoyuan City, Bade District, Yongfeng Road, No. 435

Contact

LiPOLY

旭立具備深厚技術與豐富應用經驗,匯聚各領域頂尖人才,專注開發高性能導熱及創新材料。配備先進實驗室與自動化生產設備,進行高精度測試與生產,確保產品穩定可靠。

Professional Quality

We maintain a comprehensive quality management system and have obtained international certifications.

Responsible Business Alliance

RBA Code of Conduct

Manufacture

Cleanrooms, automated equipment, and diverse molding technologies.