Liquid

Solid

Absorber

Tape

Light

Insulator

Graphite

Break

New, Non-Silicone・TIMs ——

N800C-s

17.0 W/m·K

Low outgassing

Non-silicone thermal pads do not cause electrical contact or contamination issues. With the core advantage of “zero silicone contamination,” they have become an irreplaceable choice for sensitive applications in optics, medical, and semiconductor fields. As the electronics industry advances toward higher integration, higher power, and greater precision, the demand for non-silicone thermal pads will shift from being a “silicone material alternative” to an “essential solution for specific high-end applications.”

FEATURES

/ Thermal conductivity: 17.0 W/m·K

/ It’s made by non-silicone resin materials

/ Low contact thermal resistance

/ With electrical insulation

/ Outstanding thermal conductivity

/ Applicable to optical and sensitive electric components

CONFIGURATIONS

/ Sheets form

/ Die-cuts parts

TYPICAL APPLICATION

/ High speed mass storage drives

/ Optical appliance

/ 5G base station & infrastructure

/ EV electric vehicle

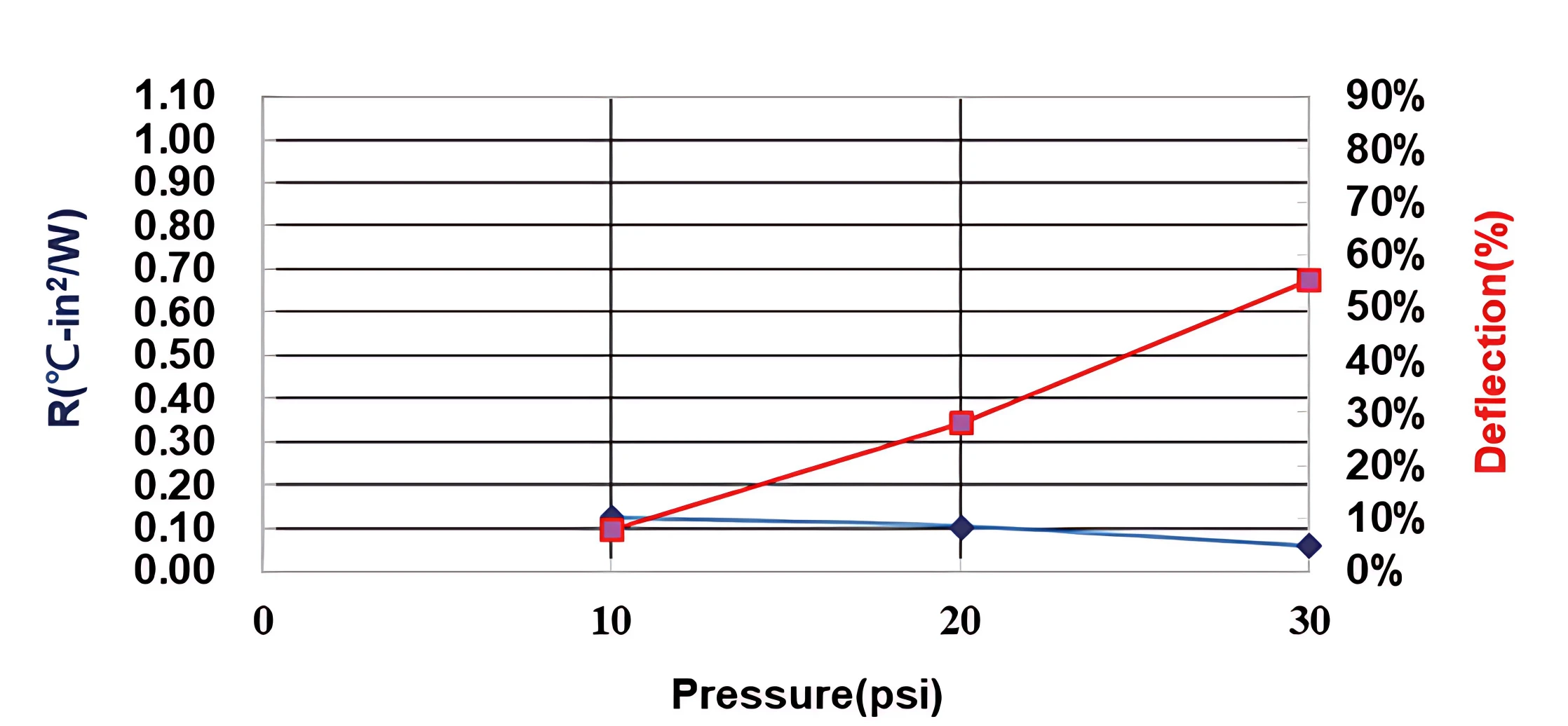

Thermal Resistance vs. Pressure vs. Deflection

TYPICAL PROPERTIES

| PROPERTY | N800C-s | UNIT | TEST METHOD |

|---|---|---|---|

| Color | Gray | - | Visual |

| Thickness | Customized | mm | ASTM D374 |

| Density | 3.3 | g/cm³ | ASTM D792 |

| Hardness | 50 | Shore OO | ASTM D2240 |

| Application temperature | -60~125 | °C | - |

| Low molecular Siloxane (D3 to D20 total) | N.D | % | Gas Chromatography |

| Outgassing CVCM (wt%) | 0.0043 | - | By LiPOLY |

| ROHS & REACH | Compliant | - | - |

| THERMAL | |||

| Thermal conductivity | 17.0 | W/m·K | ASTM D5470 |

| Thermal impedance@10 psi | 0.122 | °C-in²/ W | ASTM D5470 |

| Thermal impedance@30 psi | 0.058 | °C-in²/ W | ASTM D5470 |

Related Products

Contact

Thermal Solutions Expert

LiPOLY® Advance TIMs

Taoyuan City, Bade District, Yongfeng Road, No. 435

Contact