Liquid

Solid

Absorber

Tape

Light

Insulator

Graphite

Break

New, Silicone・TIMs ——

SH3000

3.0 W/m·K

Fiberglass reinforced

Glass fiber thermal interface composite pads are widely used in electronic devices that require heat dissipation and insulation, such as: filling air gaps between heat sinks and heat sources (such as chips) to reduce thermal resistance and improve heat dissipation efficiency; used for electrical isolation between high-power electronic components and heat sinks; suitable for automotive batteries, large communication equipment, transportation vehicles and other fields. Their customizable thickness also meets various thermal design requirements.

FEATURES

/ Thermal conductivity: 3.0 W/m·K

/ Excellent insulator

/ Reworkable

/ Fiberglass reinforced

CONFIGURATIONS

/ Roll form

/ Sheets form

/ Die-cuts parts

TYPICAL APPLICATION

/ Switching power supplies

/ Motor controls

/ EV electric vehicle

/ Automotive electronics

/ 5G base station & infrastructure

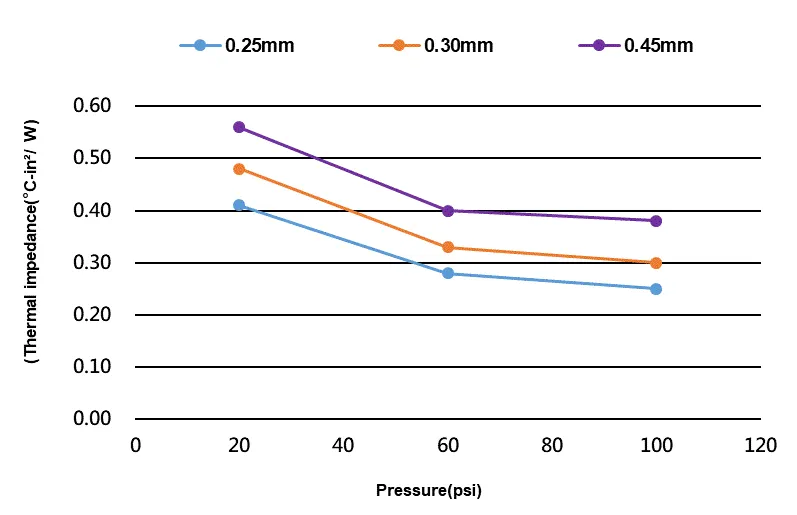

Thermal Resistance vs. Pressure

TYPICAL PROPERTIES

| PROPERTY | SH3000 | UNIT | TEST METHOD |

|---|---|---|---|

| Color | Green | - | Visual |

| Reinforced layer | Fiberglass | - | - |

| Thickness | 0.25 | 0.30 | 0.45 | mm | ASTM D374 |

| Density | 2.8 | g/cm³ | ASTM D792 |

| Hardness | 80 | Shore A | ASTM D2240 |

| Application temperature | -60~180 | °C | - |

| Dielectric breakdown | 4.0 | 5.0 | 6.0 | KV | ASTM D149 |

| ROHS & REACH | Compliant | - | - |

| THERMAL | |||

| Thermal conductivity | 3.0 | W/m·K | ASTM D5470 |

| Thermal impedance@20 psi | 0.41 | 0.48 | 0.56 | °C-in²/ W | ASTM D5470 |

| 熱阻抗@100 psi | 0.25 | 0.30 | 0.38 | °C-in²/ W | ASTM D5470 |

Related Products

Contact

Thermal Solutions Expert

LiPOLY® Advance TIMs

Taoyuan City, Bade District, Yongfeng Road, No. 435

Contact