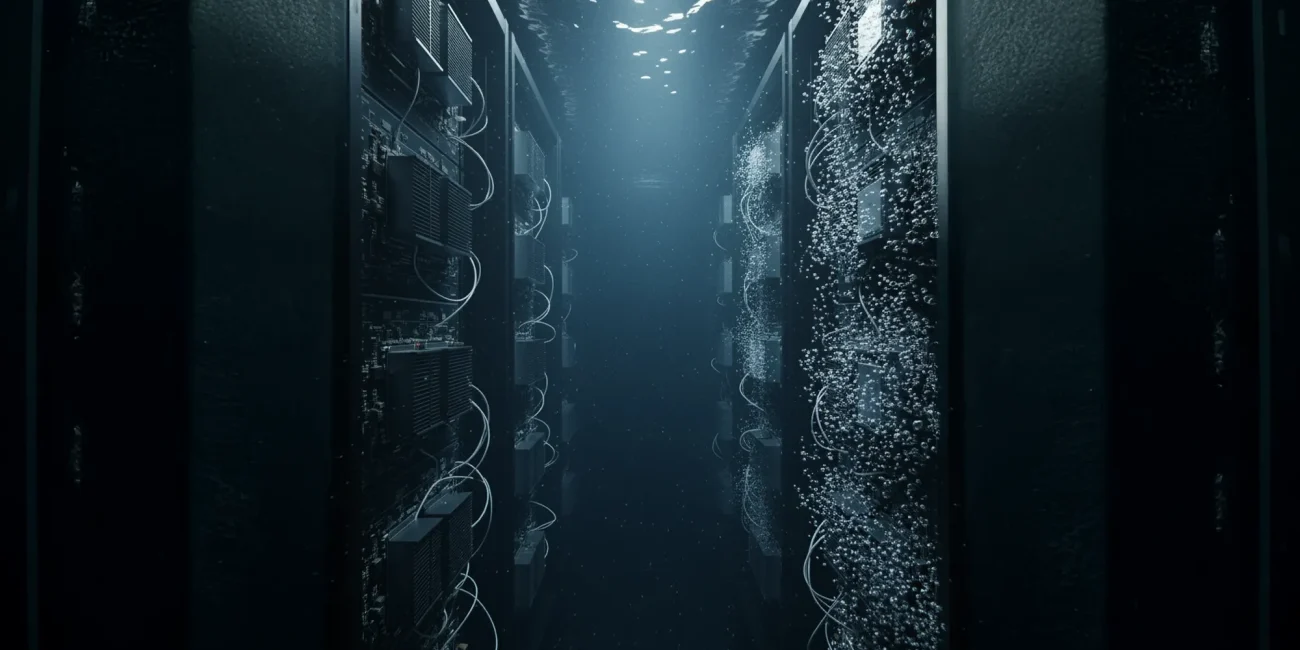

Single-Phase - Immersion Cooling System

This system uses only the liquid phase of the fluid, similar to a large closed-loop liquid cooler, and dissipates heat through forced convection. Consequently, fins are a critical design element for increasing the heat dissipation area and optimizing flow channels. For these systems, it is recommended to use thermal interface materials compatible with both the heat sink and the chip to ensure reliable heat transfer.

Two-Phase - Immersion Cooling System

Two-phase systems primarily utilize the principle of nucleate boiling to remove heat, offering extremely high heat transfer efficiency. Research indicates that, in this scenario, an excessive number of fins can actually impede bubble generation and departure, reducing efficiency. Therefore, many two-phase designs use bare or micro-structured surfaces to optimize boiling and bubble dissipation.

Single-Phase

- High Boiling Point Dielectric Fluid

- Pump-Driven Circulation

- Forced Convection Heat Transfer

- System is Simple and Easy to Maintain

Two-Phase

- Low Boiling Point Dielectric Fluid

- Natural Circulation

- Nucleate Boiling Phase Change

- Extremely High Heat Flux

Cooling Principle

Drive Method

Cooling Efficiency

Setup Cost

|

Two-Phase

|

Single-Phase

|

|

|

Heat transfer performance

|

Local convective heat transfer coefficient can reach thousands of W/m²·K; phase change enables very high heat flux and temperature stability.

|

Convective coefficient is only tens of W/m²·K; requires fins to increase area and optimized thermal interface materials to reduce interfacial resistance.

|

|

Energy efficiency

|

Maximizes energy efficiency.

|

Significantly better than air cooling; balances performance and cost.

|

|

Mechanism

|

Low-boiling dielectric fluid nucleate-boils at hotspots, carrying away latent heat; vapor condenses back to liquid. Heat transfer relies on phase change.

|

High-boiling dielectric fluid directly contacts the heat source and rejects heat via a heat exchanger without phase change, relying on natural or forced convection.

|

|

System complexity

|

High: requires sealed tanks, boiling and condensation management, and gas–liquid separation; higher design and build CAPEX.

|

Low: open or simple circulation systems; no phase-change management; simpler installation and maintenance.

|

|

Fluid cost and environment

|

Fluids are often fluorinated compounds with high cost and GWP/PFAS risks, creating strong regulatory pressure.

|

Fluid formulations can be customized, emphasizing long service life and corrosion inhibition, with lower environmental risk.

|

|

Use cases

|

Extreme heat density, space-constrained, high-performance computing facilities with boiling management and sealing capability. |

Large-scale cloud and enterprise deployments, edge computing, where high availability and low maintenance are required.

|

|

Maintenance requirements

|

Strict: prevent fluid evaporation, perform regular leak checks, and clean condensers. |

Lower: long fluid life with no phase-change degradation; maintenance similar to conventional liquid cooling.

|