Preventing Lithium Battery Thermal Runaway: The Importance of AS27-s Thermal Insulation Material

As lithium batteries are widely used across various industries, their safety has become a major concern. Lithium battery thermal runaway is a serious safety issue that can lead to fires or even explosions. This article will explore prevention measures for lithium battery thermal runaway, with special emphasis on the critical role of AS27-s thermal insulation material.

Key Measures to Prevent Lithium Battery Thermal Runaway

1. Selecting High-Quality Battery Materials

Using high-purity, stable battery materials can reduce internal reaction instability and lower the risk of thermal runaway. Choosing battery products that have undergone rigorous testing and certification is the first step in preventing thermal runaway.

2. Precise Battery Management System (BMS)

The Battery Management System is responsible for monitoring battery voltage, current, and temperature, ensuring the battery operates within safe parameters. Advanced BMS can detect abnormal conditions in real-time and take measures to prevent thermal runaway.

3. Heat Dissipation Design

Good heat dissipation design can effectively reduce the heat generated during battery operation, preventing excessive temperatures that could trigger thermal runaway. This includes using high thermal conductivity materials, installing heat sinks or fans, all of which can effectively improve heat dissipation.

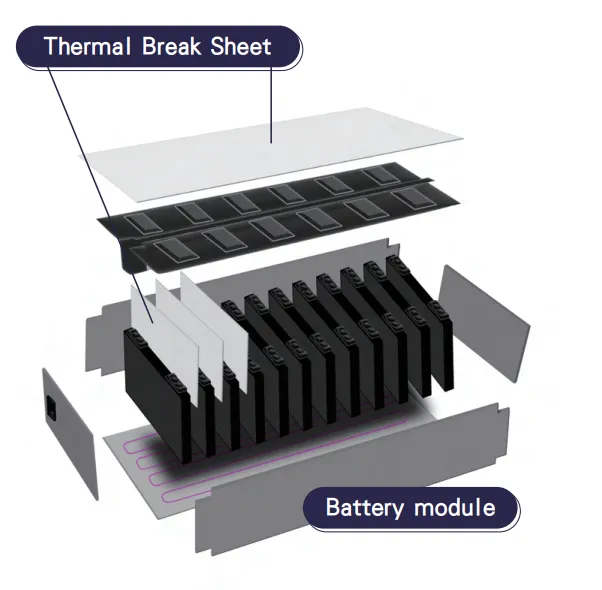

4. Application of AS27-s Thermal Insulation Material

Among all prevention measures, the application of AS27-s thermal insulation material is particularly important. AS27-s is a thermal insulation material specially designed for lithium batteries, placed between each battery cell inside the battery pack, effectively preventing thermal runaway from spreading to other battery cells, thereby avoiding chain reactions.

5. Regular Testing and Maintenance

Regular testing and maintenance of batteries can identify potential problems early and prevent thermal runaway. This includes checking the physical condition of batteries, testing battery performance, and inspecting the integrity of thermal insulation materials.

AS27-s Characteristics:

Porous Structure :

Composed of composite materials including porous silica and aluminum oxide, forming a fibrous structure with excellent thermal insulation properties.

Extremely Low Thermal Conductivity:

With a thermal conductivity of 0.009 W/m·K, it can greatly reduce heat conduction and prevent thermal energy diffusion.

High Temperature Resistance:

AS27-s can withstand temperatures up to 1300°C, ensuring thermal insulation effectiveness under extreme conditions.

Low Density:

The material has extremely low density, causing no significant increase in overall battery weight, suitable for various application scenarios.

Conclusion

Lithium battery thermal runaway is a safety issue that cannot be ignored, but by implementing multiple prevention measures, the risk of occurrence can be effectively reduced. AS27-s thermal insulation material, as an important component, provides excellent thermal insulation performance, preventing the spread of thermal runaway and ensuring the overall safety of lithium battery systems.

When selecting and designing lithium battery systems, the proper application of high-efficiency thermal insulation materials such as AS27-s is a key step in ensuring safe operation. To better protect your equipment and personnel safety, choosing high-quality thermal insulation materials and comprehensive battery management systems will be indispensable protection in lithium battery applications.