Research & Development

GAP FILLER

Absorber

Absorber

Silicone

Non-Silicone

technologies

Advance TIMs

R&D Center

Shiu Li Technology possesses cutting-edge process technologies, a comprehensive R&D laboratory, and a reliability verification laboratory for thermal interface materials. Equipped with high-spec testing instruments and automated production facilities, the company continuously enhances its technical capabilities and high-yield quality, maintaining a stable and pragmatic approach to product and technology development. In response to technological evolution, customer demands, and global environmental trends, Asahi Technology continues to produce excellent R&D outcomes in products and processes, actively deploying key industrial technologies and showcasing its top-tier R&D capabilities. Moreover, it places great emphasis on reinforcing intellectual property rights by encouraging innovation and securing patents to create a competitive advantage.

NEW PROUDCTS

Newest

We have state-of-the-art laboratories and automated production equipment to conduct high-precision testing, analysis, and manufacturing, ensuring product stability and reliability.Shiu Li custom development capabilities enable timely delivery of thermal management solutions to meet customers' unique requirements.

We have state-of-the-art laboratories and automated production equipment to conduct high-precision testing, analysis, and manufacturing, ensuring product stability and reliability.

DTT56-s Curable Thermal Grease

This product is a high thermal conductivity liquid material designed for AI chip cooling, offering excellent gap-filling capability and heat-curable properties to effectively reduce junction temperatures in high-performance computing systems. Its stable material structure makes it an ideal thermal interface material for immersion cooling, maintaining consistent thermal performance under prolonged liquid exposure and thermal cycling conditions.

In addition, this heat-curable liquid TIM for EV applications is engineered to withstand long-term thermal cycling, making it suitable for electric vehicles and other high-load operating environments. It delivers a reliable thermal management solution for advanced electronics and automotive applications requiring long-term stability and high reliability.

DTT54-s Curable Thermal Grease

DTT54-s features a thermal conductivity of 4.0 W/m·K and provides a structurally stable, high-performance thermal interface layer. It is designed for use between chips and cold plates or other heat dissipation structures, forming a low thermal interface resistance and a long-term reliable heat transfer path to effectively reduce junction temperatures. Even under prolonged immersion in cooling fluids, the material resists loss, displacement, and performance degradation, ensuring stable and reliable thermal performance during long-term operation.

Single-Phase Immersion Thermal Pad DTT61-s

Thermal pads for single-phase immersion cooling feature optimized chemical formulations tested for durability and high-temp operation. Designed for high-power uses like AI servers and data centers, they improve thermal management and system stability.

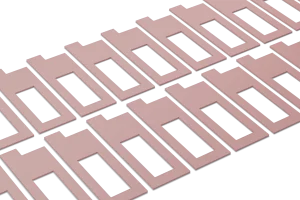

Fiberglass cloth reinforced AS50-s

The fiberglass Cloth reinforced Thermal Pads use glass fiber cloth filled with thermally conductive compounds, combining strength and heat conduction for electronics heat transfer and insulation.

DTT56-s Curable Thermal Grease

This product is a high thermal conductivity liquid material designed for AI chip cooling, offering excellent gap-filling capability and heat-curable properties to effectively reduce junction temperatures in high-performance computing systems. Its stable material structure makes it an ideal thermal interface material for immersion cooling, maintaining consistent thermal performance under prolonged liquid exposure and thermal cycling conditions.

In addition, this heat-curable liquid TIM for EV applications is engineered to withstand long-term thermal cycling, making it suitable for electric vehicles and other high-load operating environments. It delivers a reliable thermal management solution for advanced electronics and automotive applications requiring long-term stability and high reliability.

DTT54-s Curable Thermal Grease

DTT54-s features a thermal conductivity of 4.0 W/m·K and provides a structurally stable, high-performance thermal interface layer. It is designed for use between chips and cold plates or other heat dissipation structures, forming a low thermal interface resistance and a long-term reliable heat transfer path to effectively reduce junction temperatures. Even under prolonged immersion in cooling fluids, the material resists loss, displacement, and performance degradation, ensuring stable and reliable thermal performance during long-term operation.

Shiu Li Technology upholds its commitment to unveiling new products and innovations every year, bringing you surprises and excitement beyond imagination. Our product launches are not just events; they are demonstrations of power! With groundbreaking innovation, our technical team ensures your products lead the trend. This is the strength of Asahi!

Frank Jian

General Manager

No posts were found for provided query parameters.

industries

產業應用介紹

industries

產業應用

No posts were found for provided query parameters.

旭立的技術團隊來自不同領域的頂尖人才組成,專注於開發高性能導熱和創新的材料

Certification

Professional Quality

Shiu Li Technology's interface thermal conductive materials feature a comprehensive quality management system and have obtained global certifications.

9001

Published

2015

Quality System

Organizations demonstrate the ability to consistently provide products and services that meet customer requirements and comply with applicable legal and regulatory standards.

14001

Published

2015

Environmental Policy

More effectively utilize natural resources and energy while ensuring compliance with applicable environmental regulations and customer requirements or supplier agreement standards.

16949

Published

2016

Automotive Quality System

Provides a quality management system for continuous improvement, defect prevention, and reduction of variation and waste within the automotive industry supply chain operations.

080000

Published

2022

HSPM

International standard developed by IEC for managing and controlling the use of hazardous substances in products to ensure compliance with global legal and customer requirements.

D-U-N-S

Published

1962

Dun & Bradstreet

Identifies potential risks including fraud and compliance issues, ensuring suppliers or partners meet ethical and legal requirements for sustainable business operations.

ROHS

Published

2023

EU Environmental Policy

European Union directive designed to restrict the use of certain hazardous substances in electrical and electronic equipment to protect human health and environmental safety.

RBA

Published

2015

Responsible Business Alliance

Responsible Business Alliance Code of Conduct ensuring compliance with labor rights, environmental protection, and business ethics standards for sustainable electronics supply chains.

UL 94

Published

2023

Underwriters Laboratories

Plastic material flammability testing standard developed by Underwriters Laboratories, widely used for evaluating the flame retardant performance of various plastic materials.

REACH

Published

2007

Chemical Registration

Requires manufacturers and importers to demonstrate that their chemical substances are safe for health and environment, replacing high-concern substances when necessary for safety.

About us

LiPOLY® Advance TIMs

Thermal Solutions Expert

About

We believe that thermal conductivity is not just a technology but an innovative revolution. Our products combine technology and uniqueness, injecting boundless power into your products.

Company History

Continuously investing in key industrial technologies, showcasing top-notch R&D capabilities, and creating greater value for the future.

Professional Quality

Shiu Li Technology's interface thermal conductive materials feature a comprehensive quality management system and have obtained global certifications.

The global demand for thermal conductivity is growing exponentially, driving rapid advancements in thermal management technologies.

With the explosive growth in computational demands across applications and the surge in demand for AI devices, major companies worldwide are intensifying procurement efforts to stay competitive. In this context, thermal management has become critical to ensuring stable and efficient operations.