The Moss Landing Power Plant in Monterey County, California experienced a severe thermal runaway event on January 16, 2025, forcing the evacuation of 1,700 residents within a 5-mile radius. As the world's largest grid-connected battery facility with 750MW capacity, the fire burned for 72 hours before containment, destroying 80% of the 300MW battery array installed in 2020.

Liquid

Solid

Absorber

Tape

Light

Insulator

Graphite

Break

New, Non-Silicone・TIMs ——

AS17-s

0.028 W/m·K

INDUSTRIAL

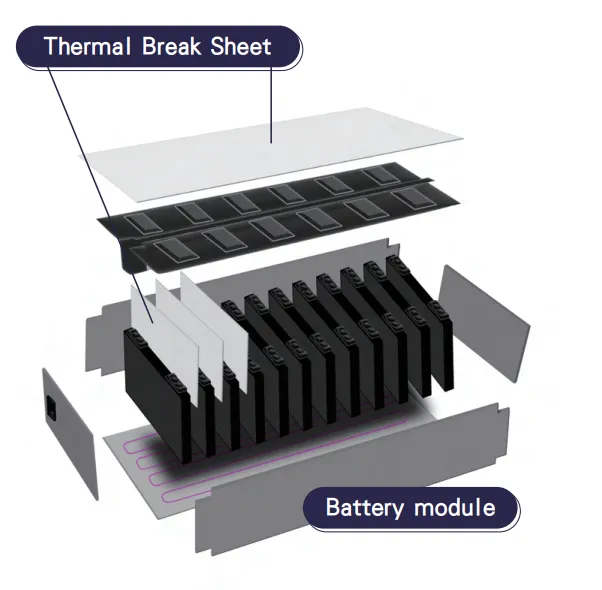

Incorporating Thermal Break Felt into battery modules allows batteries to maintain stability during intense acceleration and frequent charge-discharge cycles, while enhancing battery safety. Conversely, without sufficient thermal insulation materials, excessive battery temperatures will shorten battery lifespan and may even lead to thermal runaway.

FEATURES

/ Excellent thermal insulation performance, with a thermal conductivity of 0.028 W/m*K

/ Exceptional thermal stability, suitable for long-termuse in environments up to 1300°C

/ Good aging resistance

/ High friction coefficient and stability, providing long-term physical support for various substrates

/ Cotton felt feeling on surface

/ Complies with RoHS and REACH standards

CONFIGURATIONS

/ Roll form

/ Sheets form

TYPICAL APPLICATION

/ Industrial applications, such as industrial industry, EV related (battery modules, electromagnetic cabin fireproof and thermal insulation layer, engine compartment fireproof and thermal insulation layer, body flame retardant and thermal insulation layer, seat flame retardant lining dashboard fireproof and thermal insulation layer)

TYPICAL PROPERTIES

| PROPERTY | AS17-s | UNIT | TEST METHOD |

|---|---|---|---|

| Color | White | - | Visual |

| Thickness | Customized | mm | ASTM D374 |

| Density | 3.0 | g/cm³ | ASTM D792 |

| Application temperature | -60~1300 | °C | - |

| Short time temp. @30sec | 1650 | °C | - |

| TML(wt%) | 0.02 | - | By LiPOLY |

| Outgassing CVCM (wt%) | 0.04 | - | By LiPOLY |

| ROHS & REACH | Compliant | - | - |

| THERMAL | |||

| Thermal [email protected] | 0.028 | W/m·K | ASTM D5470 |

| Thermal impedance@10 psi | 56 | °C-in²/ W | ASTM D5470 |

Related Products

Contact

Thermal Solutions Expert

LiPOLY® Advance TIMs

Taoyuan City, Bade District, Yongfeng Road, No. 435

Contact